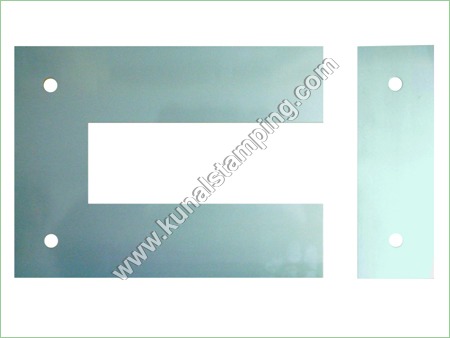

3 Phase Core Stamping

MOQ : 10 Units

3 Phase Core Stamping Specification

- Product Type

- 3 Phase Core Stamping

- Material

- CRGO

- Surface Treatment

- Polished

- Size

- Standard

- Color

- Silver

- Warranty

- Yes

About 3 Phase Core Stamping

With the aid of 3 phase core stamping presses and dies, sheet metal may be cold-formed into a variety of shapes during the metal stamping process. Blanks, which are pieces of flat sheet metal, are fed into a stamping press, which shapes the metal using a tool and die surface. Placing the material to be stamped between die portions causes pressure to shape and shear the material into the final form that is required for the finished good or component. Metal stamping includes 3 phase core stamping. Stamping replaced die forging and machining as the method for producing parts, drastically lowering the cost of the component.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electrical Lamination Stampings Category

CVT Stamping Core

Size : Standard

Surface Treatment : Galvanized

Color : Grey

Weight : 350 g

Dimension (L*W*H) : 12 x 10 x 8 cm

Material : Silicon Steel

Electric Lamination Core

Size : Customizable

Surface Treatment : Rust Proof Coating

Color : Grey

Weight : 2.8 kg

Dimension (L*W*H) : 150 mm x 90 mm x 50 mm

Material : Cold Rolled Grain Oriented Silicon Steel

Long Type Stamping Core

Size : Long Type (customizable)

Surface Treatment : Nickel Plated

Color : Silver

Weight : Lightweight

Dimension (L*W*H) : Custom as per requirement

Send Inquiry

Send Inquiry