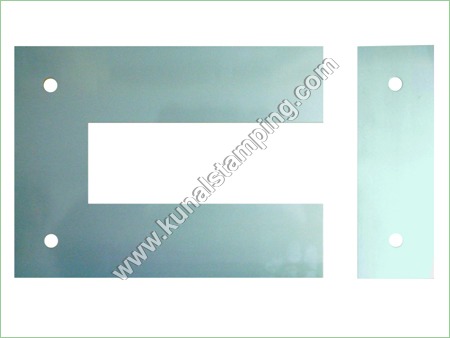

Electrical Lamination Core Stamping

Electrical Lamination Core Stamping Specification

- Surface Treatment

- Galvanized / Annealed / Oiled

- Working Stroke

- Standard

- Size

- Customized

- Color

- Metallic Grey

- Dimension (L*W*H)

- Depends on Drawing / Custom

- Weight

- Variable as per Design

About Electrical Lamination Core Stamping

Since our establishment, we have been delicately engaged in offering our esteemed clients the best quality Electrical Lamination Core Stamping. Manufactured using optimum quality metal materials and modern technology as per the international standards. Offered product is widely used in electronic sector for making different types of transformers. This Electrical Lamination Core Stamping is provided to the clients in different specifications depending upon their requirements.

Features:

-

Sturdily constructed

-

Excellent finish

-

Easy installation

-

Durability

Tailor-Made for Efficiency

Each core stamping is crafted precisely to your drawing and design requirements, ensuring seamless integration and maximum efficiency in your electrical systems. We offer flexibility in dimension, stroke, and weight to meet the varied demands of manufacturers across industries.

Advanced Surface Treatments

Our lamination cores undergo surface treatments such as galvanization, annealing, and oiling. These coatings enhance durability, reduce corrosion, and improve the lifespan and performance of your electrical components, making them ideal for rigorous operational environments.

FAQs of Electrical Lamination Core Stamping:

Q: What is electrical lamination core stamping used for?

A: Electrical lamination core stamping is primarily used in the manufacturing of transformers, motors, and other electrical devices. It minimizes energy loss by reducing eddy currents and provides efficient magnetic flux paths.Q: How is the size and dimension determined for each order?

A: Sizes and dimensions are customized based on customer-provided drawings and technical requirements. Each stamping is tailored to ensure an exact fit and compatibility with specific equipment.Q: What surface treatments are available and what are their benefits?

A: We offer galvanized, annealed, and oiled surface treatments. These enhance resistance to corrosion, reduce wear, and extend the operational life of the lamination core.Q: Where are these lamination core stampings manufactured and supplied from?

A: Our products are manufactured and supplied from India. We serve clients both domestically and internationally, acting as importer, manufacturer, and supplier.Q: When should galvanization, annealing, or oiling be chosen for the surface treatment?

A: The choice depends on the application and operational requirements. Galvanization is best for corrosion resistance, annealing for improved magnetic properties, and oiling for easy handling and installation.Q: What is the typical process for ordering customized electrical lamination core stampings?

A: Clients provide detailed drawings and specifications, after which our team assesses and develops a tailored solution, including selecting the ideal materials, dimensions, and treatments.Q: How does using customized lamination core stampings benefit my electrical applications?

A: Customized laminations optimize performance, reduce electrical losses, and ensure the right fit for your equipment, resulting in greater efficiency and longevity in operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Lamination Stampings Category

CVT Stamping Core

Size : Standard

Color : Grey

Surface Treatment : Galvanized

Weight : 350 g

Dimension (L*W*H) : 12 x 10 x 8 cm

Material : Silicon Steel

Long Type Stamping Core

Size : Long Type (customizable)

Color : Silver

Surface Treatment : Nickel Plated

Weight : Lightweight

Dimension (L*W*H) : Custom as per requirement

Electric Lamination Core

Size : Customizable

Color : Grey

Surface Treatment : Rust Proof Coating

Weight : 2.8 kg

Dimension (L*W*H) : 150 mm x 90 mm x 50 mm

Material : Cold Rolled Grain Oriented Silicon Steel

Send Inquiry

Send Inquiry