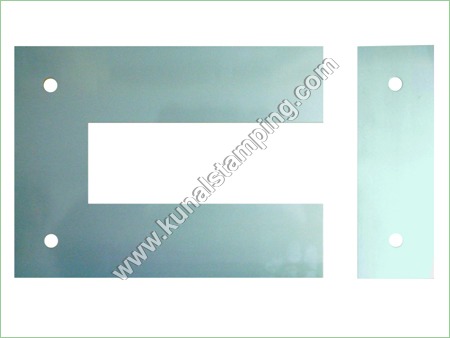

CVT Stamping Core

CVT Stamping Core Specification

- Product Type

- CVT Stamping Core

- Material

- Silicon Steel

- Surface Treatment

- Galvanized

- Gross Power

- 5 W

- Size

- Standard

- Color

- Grey

- Dimension (L*W*H)

- 12 x 10 x 8 cm

- Weight

- 350 g

About CVT Stamping Core

Being a client-centric organization, we are actively engaged in offering our valuable clients the finest quality CVT Stamping Core . Manufacture using utmost quality materials and modern technology, our offered core is widely used in different types of transformers. This CVT Stamping Core is made available in varied counts of thickness as per the requirements of the clients. In addition to this, clients can avail this core within the promised period of time, across the nation.

Key Features:

-

Accurate dimensions

-

Precisely engineered

-

Durable finish

-

Long operational life

The thickness like 0. 50mm, 0. 35 mm, 0. 30 mm

Precision Engineered Silicon Steel Core

Constructed from high-grade silicon steel, the CVT Stamping Core ensures optimal magnetic properties to efficiently direct current and voltage within transformers. The galvanization process further boosts its resistance to environmental wear, making it a dependable choice for manufacturers and suppliers.

Ideal for Transformer Applications

With its compact dimensions and lightweight design, the core fits seamlessly into standard transformer builds. The 5 W gross power capacity supports stable operation, offering manufacturers a sturdy and reliable component for producing current and voltage transformers in diverse electrical settings.

FAQs of CVT Stamping Core:

Q: How is the CVT Stamping Core typically used in transformers?

A: The CVT Stamping Core is primarily used in current and voltage transformers where it acts as the central magnetic path, helping to direct and regulate electromagnetic fields necessary for transformer function.Q: What benefits does the galvanized surface treatment provide?

A: Galvanized coating on the core enhances resistance to corrosion and environmental damage, significantly extending the components lifespan and ensuring reliable performance even in challenging conditions.Q: Where can I source the CVT Stamping Core in India?

A: This product is available through authorized importers, manufacturers, and suppliers across India. Many electrical component distributors offer the core in standard sizes for immediate use in transformer assemblies.Q: When should the core be replaced during transformer maintenance?

A: It is recommended to inspect the core during regular transformer maintenance intervals. Replacement is generally necessary if there are signs of damage, corrosion, or diminished magnetic efficiency affecting transformer performance.Q: What process is used in manufacturing the CVT Stamping Core?

A: The core is produced by precision stamping silicon steel sheets, followed by assembly to the required dimensions and then applying a galvanizing treatment to improve durability and conductivity.Q: What are the practical benefits of using silicon steel in transformer cores?

A: Silicon steel offers superior magnetic permeability and low electrical losses, which leads to efficient power conversion, reduced heat generation, and overall improved performance and longevity of the transformer.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Electrical Lamination Stampings Category

LTL Stamping Core

Minimum Order Quantity : 10 Units

Color : Silver

Size : Standard

Surface Treatment : Polished

Material : CRGO

3 Phase Core Stamping

Minimum Order Quantity : 10 Units

Color : Silver

Size : Standard

Surface Treatment : Polished

Material : CRGO

Electric Lamination Core

Color : Grey

Size : Customizable

Surface Treatment : Rust Proof Coating

Material : Cold Rolled Grain Oriented Silicon Steel

Weight : 2.8 kg

Electrical Lamination Core Stamping

Color : Metallic Grey

Size : Customized

Surface Treatment : Galvanized / Annealed / Oiled

Weight : Variable as per Design

Send Inquiry

Send Inquiry