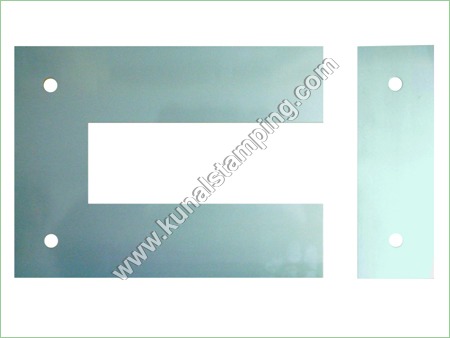

Electrical Lamination Core

Electrical Lamination Core Specification

- Material

- Cold Rolled Grain Oriented (CRGO) Silicon Steel

- Size

- Standard and Custom Sizes Available

- Color

- Silver Grey

- Dimension (L*W*H)

- Customized

- Weight

- Depends on size and material thickness

About Electrical Lamination Core

We are remarkable entity, actively engaged in offering a superior quality range of Electrical Lamination Core. This core is manufactured using the finest quality steel that helps in maintaining less current load. Our offered Electrical Lamination Core is widely used in inverter manufacturing industry and transformer manufacturing industry as per the need of the clients. In addition to this, we also offer this core in different specifications in order to cater to the need of the clients.

Features:

-

Robust construction

-

Flawless finish

-

Resistance to corrosion

-

Dimensionally accurate

Superior Material for Enhanced Efficiency

Engineered with CRGO Silicon Steel, these lamination cores provide minimized core losses and higher energy efficiency in electrical transformers and equipment. The precise grain orientation of the material ensures superior magnetic properties, making them an optimum choice for high-performance electrical infrastructure.

Customizable Dimensions for Diverse Applications

We understand that every project is unique. Our Electrical Lamination Cores are available in both standard and custom sizes, allowing you to specify exact dimensions that fit your equipment. This flexibility ensures seamless integration into various transformer and motor manufacturing processes.

FAQs of Electrical Lamination Core:

Q: How is the Electrical Lamination Core manufactured?

A: The core is produced by precision cutting Cold Rolled Grain Oriented (CRGO) Silicon Steel sheets into desired shapes and sizes, then layering and assembling them to form the finished lamination core. Specialized equipment ensures accurate dimensions and consistent quality throughout.Q: What is the primary usage of CRGO lamination cores?

A: These cores are primarily used in transformers, electrical reactors, and various power distribution applications. Their main role is to direct and regulate magnetic flux efficiently, resulting in reduced energy loss and improved electrical performance.Q: When should I consider using a custom-sized lamination core?

A: Custom-sized cores are recommended when your equipment has unique spatial requirements or when off-the-shelf sizes do not provide the optimal fit for your transformer or machinery design. Tailored dimensions enhance efficiency and compatibility.Q: Where can I source Electrical Lamination Cores in India?

A: You can source these lamination cores from various reputable importers, manufacturers, and suppliers across India. Many companies offer nationwide shipping and support, ensuring accessibility regardless of your location.Q: What benefits does CRGO silicon steel offer compared to other materials?

A: CRGO silicon steel is specifically engineered for electrical applications, offering superior magnetic properties, lower core losses, and high efficiency. This results in increased durability and reduced operating costs for equipment using these lamination cores.Q: How does the provided color and finish impact the product?

A: The Silver Grey color is a result of the CRGO treatment process and provides a smooth, corrosion-resistant surface. This not only enhances the aesthetic appeal but also contributes to the longevity and durability of the core in operational environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Lamination Stampings Category

Long Type Stamping Core

Surface Treatment : Nickel Plated

Size : Long Type (customizable)

Color : Silver

Dimension (L*W*H) : Custom as per requirement

Weight : Lightweight

Electric Lamination Core

Surface Treatment : Rust Proof Coating

Size : Customizable

Color : Grey

Dimension (L*W*H) : 150 mm x 90 mm x 50 mm

Weight : 2.8 kg

Material : Cold Rolled Grain Oriented Silicon Steel

Electrical Lamination Core Stamping

Surface Treatment : Galvanized / Annealed / Oiled

Size : Customized

Color : Metallic Grey

Dimension (L*W*H) : Depends on Drawing / Custom

Weight : Variable as per Design

Send Inquiry

Send Inquiry