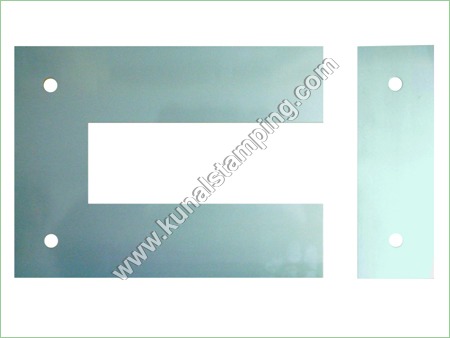

CRGO Lamination Core

CRGO Lamination Core Specification

- Material

- Cold Rolled Grain Oriented (CRGO) Silicon Steel

- Surface Treatment

- Galvanized/Coated

- Size

- Customized

- Color

- Silver Gray

- Dimension (L*W*H)

- Custom/As per requirement

- Weight

- Variable/Depends on size

About CRGO Lamination Core

Our enterprise is instrumental in offering our valuable clients the finest quality CRGO Lamination Core. The offered core is manufactured from utmost quality steel available in M2, M3, M4, M5, M6 grades, as well as in HIB CRGO grades of ZDKH, ZDMH, TCH-0, TCH-1, as per the requirements of the clients. Our offered core is highly demanded among the clients for different types of transformer. Moreover, clients can avail this CRGO Lamination Core at industry-leading prices.

Features:

-

Impeccable finish

-

Sturdy construction

-

Superior finish

-

Durability

Custom-Built for Precision Performance

CRGO Lamination Cores are manufactured according to client-specific requirements, ensuring a precise fit and maximum performance. With versatile sizing options and various surface treatments, these cores are suitable for a wide range of transformer applications, providing superior magnetic flux and minimal core losses.

Strict Quality Control and Manufacturing Expertise

Our advanced manufacturing process includes stringent quality checks, from material selection to final surface treatment. As a trusted importer and supplier in India, we prioritize high-grade CRGO silicon steel and cutting-edge galvanizing techniques to deliver robust and reliable lamination cores for every industry need.

FAQs of CRGO Lamination Core:

Q: How are CRGO Lamination Cores manufactured to meet custom size requirements?

A: CRGO Lamination Cores are produced using precision equipment and techniques that allow for customization in length, width, height, and weight. Clients can specify dimensions to fit their exact application, ensuring a tailored solution for diverse transformer and electrical device designs.Q: What is the main benefit of using Cold Rolled Grain Oriented (CRGO) Silicon Steel in lamination cores?

A: CRGO Silicon Steel offers exceptionally low core loss and high magnetic permeability, making it ideal for transformers. This results in improved energy efficiency, reduced heat generation, and enhanced performance throughout the lifespan of the electrical equipment.Q: When should CRGO Lamination Cores be used over other core materials?

A: CRGO Lamination Cores are best used in applications requiring high-efficiency transformers or electrical devices where minimizing energy loss is critical. These cores are the preferred choice for power distribution, transmission, and specialized industrial transformers due to their superior magnetic properties.Q: Where can you source CRGO Lamination Cores with customized dimensions in India?

A: You can source high-quality, custom-sized CRGO Lamination Cores directly from established importers, manufacturers, and suppliers like us in India. We cater to individual project requirements and ensure prompt delivery nationwide.Q: What is the process of surface treatment for the lamination cores?

A: The surface of each core undergoes galvanization or a specialized coating process. This protective layer prevents oxidation and corrosion, thereby enhancing the cores lifespan and ensuring reliable long-term operation in various environments.Q: How are CRGO Lamination Cores utilized in electrical equipment?

A: These lamination cores are commonly stacked and assembled inside transformers or reactors to channel magnetic flux efficiently. Their unique grain orientation and treatment minimize eddy current losses, which is crucial for maintaining low operating temperatures and heightened device reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Electrical Lamination Stampings Category

CVT Stamping Core

Color : Grey

Size : Standard

Weight : 350 g

Material : Silicon Steel

Dimension (L*W*H) : 12 x 10 x 8 cm

Surface Treatment : Galvanized

Electric Lamination Core

Color : Grey

Size : Customizable

Weight : 2.8 kg

Material : Cold Rolled Grain Oriented Silicon Steel

Dimension (L*W*H) : 150 mm x 90 mm x 50 mm

Surface Treatment : Rust Proof Coating

Electrical Lamination Core Stamping

Color : Metallic Grey

Size : Customized

Weight : Variable as per Design

Dimension (L*W*H) : Depends on Drawing / Custom

Surface Treatment : Galvanized / Annealed / Oiled

Send Inquiry

Send Inquiry