EI Core Dimension

EI Core Dimension Specification

- Feature

- High permeability, Low Iron Loss

- Shape

- Rectangular

- Insulation Material

- Insulated as per requirement

- Efficiency

- High (>95%)

- Humidity %

- Up to 95% RH

- Overheating Protection

- Used with transformer protection

- Power Factor

- High (>0.98 typical in assembled transformer)

- Surface Finish

- Polished / Coated

- Application

- Transformers, Electrical Equipment

- Protection Level

- Standard

- Frequency (MHz)

- 50Hz / 60Hz

- Rated Voltage

- Depends on transformer design

- Energy Consumption

- Low core loss

- Output Type

- Core output for winding

- Color

- Grey / Silver

- Dimension (L*W*H)

- Varies, refer to EI core table

- Weight

- As per size and type

- Phase

- Single Phase / Three Phase

- Input Voltage

- Depends on transformer specification

- Connection Type

- Wound core, mechanical

- No Of Poles

- 2

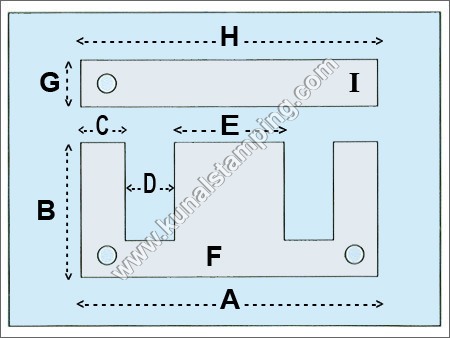

About EI Core Dimension

EI Dimension

ALL SIZE AREA IN : MM

| SR. | SIZE | A | B | C | D | E | F | G | H | I |

| NO. |

|

|

|

|

|

|

|

|

| Hole Size |

| 1 | 1 NO | 28.6 | 22 | 4.76 | 4.76 | 9.53 | 4.76 | 4.76 | 28.6 |

|

| 2 | 17 NO | 36.1 | 25.4 | 6.35 | 6.35 | 12.7 | 6.35 | 6.35 | 36.1 |

|

| 3 | 17 SPL | 41.5 | 27.5 | 6.35 | 8 | 12.7 | 6.35 | 6.35 | 41.5 |

|

| 4 | 12 NO | 48.1 | 31.75 | 8.02 | 8.02 | 16.04 | 8 | 8 | 48.1 |

|

| 5 | 23 NO | 57.15 | 38.1 | 9.52 | 9.52 | 19.05 |

|

|

|

|

| 6 | 30 NO | 60 | 40 | 10 | 10 | 20 |

|

|

|

|

| 7 | 45 NO | 67.5 | 44.45 | 11.25 | 11.25 | 22.5 |

|

|

| 3 |

| 8 | 15 NO | 76.2 | 50.8 | 12.7 | 12.7 | 25.4 | 12.7 | 12.7 | 76.2 |

|

| 9 | 33 NO | 94 | 56 | 14 | 14 | 28 | 14 | 14 | 84 | 6.75 |

| 10 | 3 NO | 96.25 | 63.5 | 16.04 | 16.04 | 32.06 | 16.04 | 16.04 | 96.25 | 6.75 |

| 11 | 4 NO OR 16 | 114.3 | 76.2 | 19.05 | 19.05 | 38.1 | 19.05 | 19.05 | 114.3 | 6.75 |

| 12 | 6 B | 133.35 | 88.9 | 22.22 | 22.22 | 44.45 | 22.22 | 22.22 | 133.4 | 6.75 |

| 13 | 7 NO OR 43 | 152.4 | 101.6 | 25.4 | 25.4 | 51.8 | 25.4 | 25.4 | 152.4 | 6.75 |

| 14 | 7 B | 190.5 | 127 | 31.75 | 31.75 | 63.5 | 31.75 | 31.75 | 190.5 | 8 |

| 15 | 8 NO | 184.15 | 146.05 | 25.4 | 41.5 | 50.8 | 25.4 | 25.4 | 184.2 | 8 |

| 16 | 8 B | 234.95 | 158.75 | 38.1 | 41.28 | 76.2 | 38.1 | 38.1 | 235 | 12 |

| 17 | 9 NO (9 X 12) | 228.6 | 152.4 | 38.1 | 38.1 | 76.2 | 38.1 | 38.1 | 228.6 | 12.5 |

| 18 | 10 (101/2 X 14) | 266.7 | 177.8 | 44.45 | 44.45 | 88.9 | 44.45 | 44.45 | 266.7 | 12.5 |

| 19 | 100 NO(12 X 16) | 304.8 | 203.2 | 50.8 | 50.8 | 101.6 | 50.8 | 50.8 | 304.8 | 12.5 |

| 20 | 200 NO (15 X20) | 381 | 254 | 63.5 | 63.5 | 127 | 63.5 | 63.5 | 381 | 12.5 |

Versatile Application for Electrical Equipment

EI Core Dimensions are engineered to suit a wide range of applications in transformers and various electrical equipment. The customizable sizes and phase options offer flexibility to meet the unique demands of industrial, commercial, and residential projects. With their robust design and adaptable specifications, these cores maintain stable performance across different environments.

Optimal Efficiency and Low Energy Consumption

Integrating high permeability and low iron loss materials, these EI cores deliver maximum electromagnetic efficiency, boasting energy consumption savings and operational stability. Designed for continuous operation, the cores offer a high power factor and superior insulation for reduced core losses, ensuring minimal heat generation and reliable functioning over time.

FAQs of EI Core Dimension:

Q: How are EI Core Dimensions selected for a specific transformer application?

A: EI Core Dimensions are chosen based on the transformers size, type, required voltage, and frequency. Refer to the EI core table for precise length, width, and height specifications that match the projects demands.Q: What benefits do high permeability and low iron loss provide in EI cores?

A: High permeability ensures efficient magnetic flux transfer, while low iron loss minimizes energy wasted as heat, resulting in improved transformer efficiency and lower operational costs.Q: When should overheating protection be considered for EI Core installations?

A: Overheating protection should be integrated whenever the core is used in transformers or electrical equipment handling variable loads, ensuring safe operation and extended lifespan.Q: Where are EI cores typically used within electrical systems?

A: EI cores are predominantly utilized in transformer assemblies, power supplies, and voltage regulators within industrial, commercial, and residential electrical installations.Q: What is the process for winding and integrating an EI core into a transformer?

A: The EI core is wound and mechanically assembled with insulated wire as per the transformer specification, followed by electrical testing to confirm performance and adherence to safety standards.Q: How does surface finish affect the durability of EI cores?

A: Polished or coated surface finishes enhance the cores resistance to corrosion and physical wear, maintaining performance integrity even in humid environments up to 95% RH.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry